Description

This three-phase oil-immersed distribution transformer is with a new insulation structure to improve short-circuit resistance.

The iron core is made of high-quality cold-rolled silicon steel sheets. The high-voltage winding is made of high-quality oxygen-free copper wire and adopts a multi-layer cylindrical structure. All fasteners are treated with special anti-loosening treatment.

The three-phase oil-immersed distribution transformer has the characteristics of high efficiency and low loss, which can save a lot of electricity consumption and operating costs, and has significant social benefits. It is a high-tech product promoted by country.

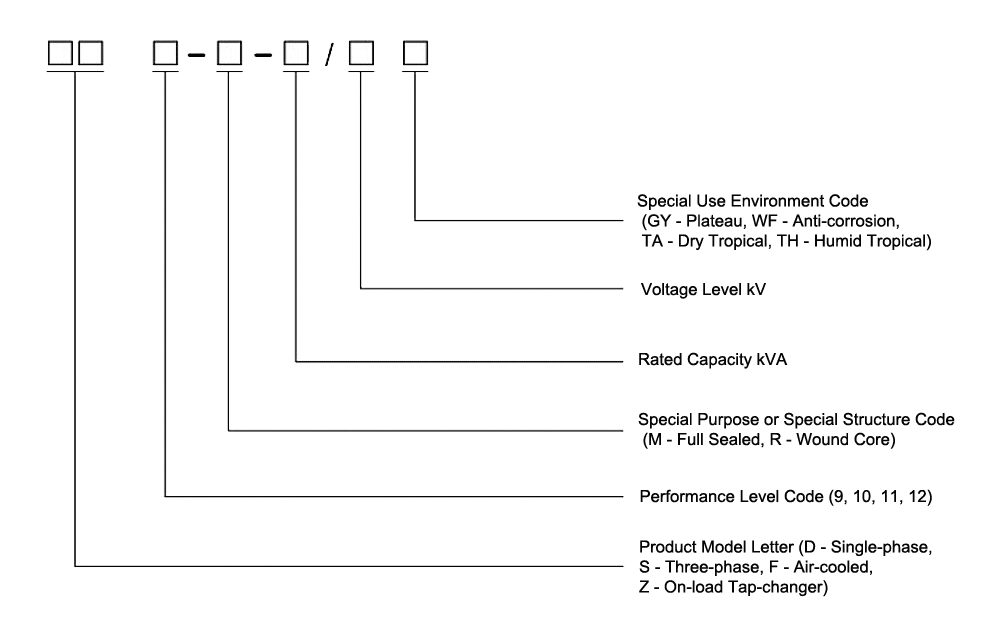

Model Designation

Reliable Structure

Based on the traditional structure and mature technology, our company has made many improvements, such as:

◆ Adoption of spiral coils with longitudinal oil channels for improved internal heat dissipation.

◆ Improved effective support on the coil end face for better resistance to short-circuit current.

◆ Adoption of a new lifting structure and body positioning structure to ensure greater reliability during long-distance transportation and operation.

◆ we also have many unique and reliable structures at your service.

The selection of transformers with higher performance level will have a higher level of technology.

Technical Parameters

| Rated Capacity(KVA) | Voltage Group(KV) | Vector Group | No-load Loss(W) | Load Loss(W) | No-load Current(%) | Impedance Voltage(%) | Weight(kg) | Dimensions L×W×H(mm) | Mounting Dimensions(mm) |

| 50 | 20 10 | Yyn0 Dyn11 | 0.17 | 1.15 | 2.0 | 5.5 | 515 | 920×610×1150 | 450/380 |

| 100 | 0.23 | 1.92 | 1.8 | 695 | 920×680×1250 | 550/450 | |||

| 125 | 0.27 | 2.26 | 1.7 | 810 | 960×780×1270 | 550/470 | |||

| 160 | 0.29 | 2.69 | 1.6 | 950 | 1160×710×1380 | 550/520 | |||

| 200 | 0.34 | 3.16 | 1.5 | 1065 | 1190×730×1340 | 550/520 | |||

| 250 | 0.41 | 3.76 | 1.4 | 1200 | 1280×820×1360 | 650/550 | |||

| 315 | 0.49 | 4.53 | 1.4 | 1360 | 1380×910×1390 | 650/550 | |||

| 400 | 0.58 | 5.47 | 1.3 | 1580 | 1430×950×1470 | 650/550 | |||

| 500 | 0.69 | 6.58 | 1.2 | 1790 | 1520×1020×1510 | 750/600 | |||

| 630 | 0.83 | 7.87 | 1.1 | 2100 | 1680×1150×1530 | 850/660 | |||

| 800 | 0.98 | 9.41 | 1.0 | 2420 | 1810×1280×1580 | 850/660 | |||

| 1000 | 1.15 | 11.54 | 1.0 | 3080 | 1840×1290×1690 | 850/660 | |||

| 1250 | 1.4 | 13.94 | 0.9 | 3460 | 1850×1300×1730 | 850/660 | |||

| 1600 | 1.7 | 16.67 | 0.8 | 4015 | 1920×1350×1790 | 850/700 | |||

| 2000 | 2.18 | 20.43 | 0.8 | 4555 | 2020×1770×2290 | 820/820 | |||

| 2500 | 2.56 | 21.85 | 0.8 | 5400 | 2080×1800×2280 | 1070/1070 | |||

| Note: 1. High-voltage tapping range is ±5% or ±2x2.5%; Frequency is 50Hz. | |||||||||